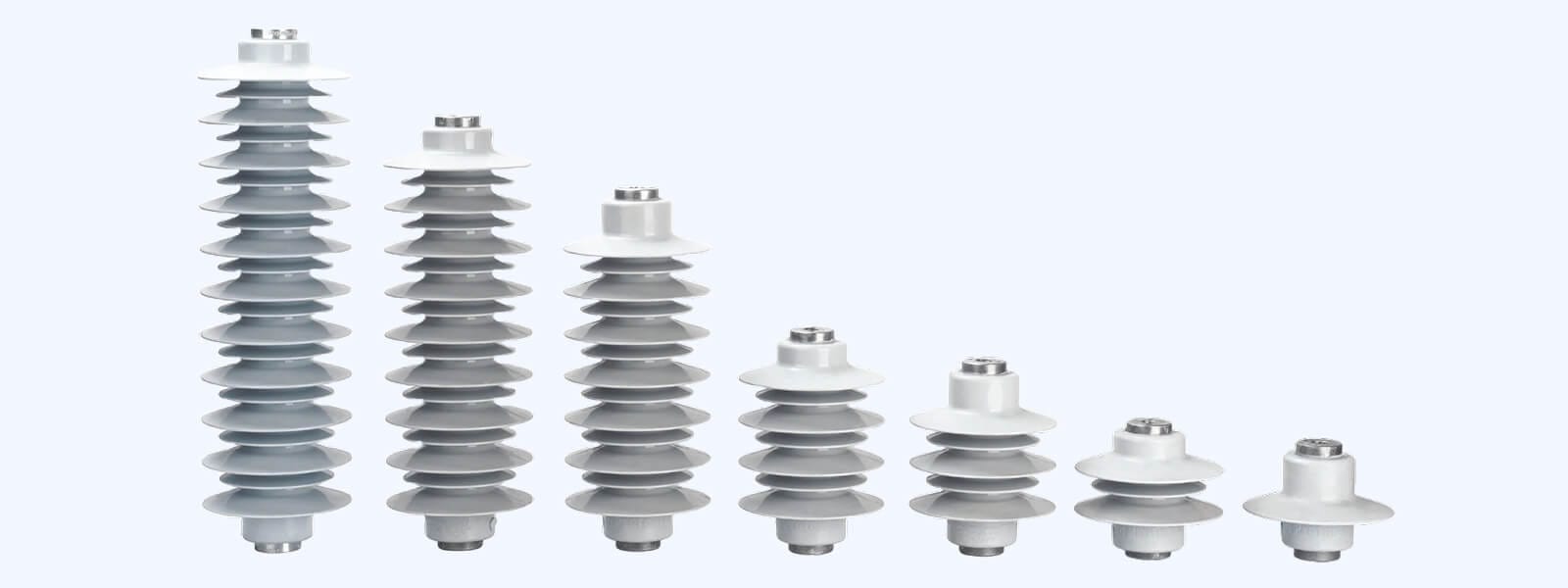

Engineers and designers have no doubts about the quality of surge arresters from industry leaders. However, not everyone knows that a Polish company produces these devices better than the global competition. Especially design offices and project managers in particular should pay attention. Learn more about the main advantages of PROXAR arresters that set them apart from the other products on the market.

Free consultationTable of contents:

- What are surge arresters? What are they used for?

- Evolution of arrester design and its benefits

- Protektel - Polish manufacturer of the PROXAR family of arresters

- What distinguishes PROXAR arresters?

- Possibilities of adjusting PROXAR parameters to your needs

- When you choose PROXAR, you get more than just a surge arrester

Everyone knows what a surge arrester is. After all, to be able to bid in a tender is to provide equipment with certain parameters. However, a creative designer or project engineer and an experienced construction manager know that the object of sale in this case is not just a surge arrester… and this is where the PROXAR brand advantage begins.

What are surge arresters? What are they used for?

A brief definition explains that surge arresters are electrical devices whose purpose is to protect electrical and electronic equipment from surges. Overvoltages, on the other hand, are sudden and short-lived voltage spikes that can be very damaging. They can come from outside (e.g., from lightning) or occur in the power grid (e.g., when switching on or off high-powered electrical loads).

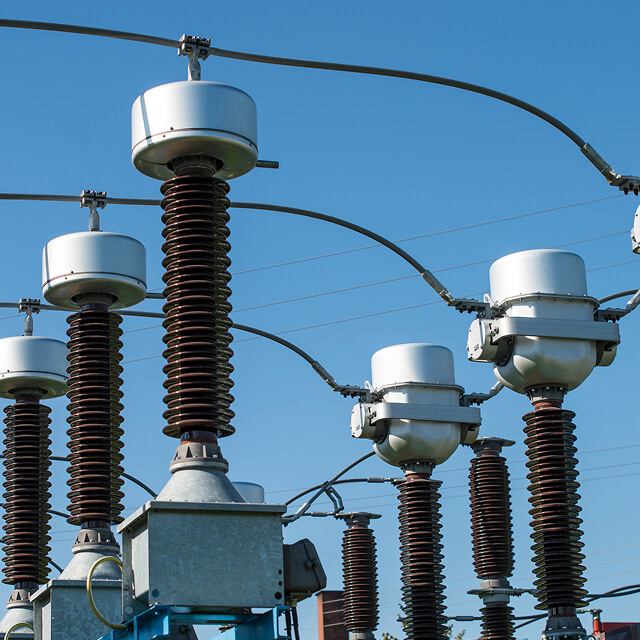

Surge arresters of various types are commonly used in home and telecommunications installations. Properly selected, they provide effective protection, which is why they are also - or perhaps primarily - used in industrial business and the power industry. Surge arresters for such applications must have parameters that enable them to effectively protect critical equipment and infrastructure, often of enormous value. This is why they are manufactured only by the best ones in the industry.

Evolution of arrester design and its benefits

The first protection devices were spark arresters, which protected electrical installations from the effects of surges, mainly atmospheric ones. As a result of technological advances, more and more advanced solutions began to be executed, based on spark gaps and semiconductor elements (such as carborundum, or SiC silicon carbide). Devices "enclosed" in porcelain sheaths in this way were called lightning arresters. These devices successfully protected objects from the destructive effects of various types of surges, but they were not free from imperfections.

Technological advances created the need for better and more effective protection of electrical equipment from surges that no longer came from the outside, but also generated in the power grids themselves. To this end, varistors began to be used in the design of arresters. These are semiconductor elements, with highly non-linear voltage-current characteristics, which allow very effective overvoltage dissipation without the formation of adverse phenomena such as spark re-ignition or follow currents. Nowadays, the most demanding implementations usually use surge arresters based on high-quality varistors in ZnO varistor technology.

Protektel - Polish manufacturer of the PROXAR family of arresters

Protektel's history begins in the 1990s at ZWAR company, although formally the manufacturer started their work operations in 2002. It took many years to refine the concept of a modern surge arrester. And not much less to put into production the whole family of these devices, under the Polish PROXAR brand

All of Protektel's surge arresters are manufactured at the company's headquarters, in Przasnysz, Poland. Of course, the main components such as varistors are imported, as that is the only way to ensure the consistently high quality of the finished PROXAR arresters. In addition, they are also distinguished at least by their internal construction, which, above all, ensures adequate mechanical strength.

The production process of PROXAR arresters involves several stages, including the braiding. The core of the arrester is braided with a special polyamide fiber in a unique braid construction process, protected by Protektel's patent. It is this durable, properly applied braid that is responsible for the mechanical strength of PROXAR arresters, so they can be installed in a variety of locations, including non-standard ones, and to function faultlessly even for several decades.

What distinguishes PROXAR arresters?

Taking into account the innovative polyamide braiding technology, it can be said that Protektel's innovations in the design of PROXAR arresters already started inside them. While the mechanical strength of such devices is important in many applications, it turns out that it is crucial to meet certain parameters.

This brings us to PROXAR's most important advantage over the competition.

It turns out that Protektel’s arresters have much better parameters than the alternative products of the industry leaders. Details can be found in the table below:

| Manufacturer | Type | Qrs [C] according to EN 60099-4:2014-01 | Wth [kJ] according to EN 60099-4:2014-01 | IEC 60099-4:2014 class | IEC 60099-4:2009 class | ||

| Protektel | PROXAR-IIN AC | 1,6 | ≥ 1,0 | 7,0 | ≥ 4 | SL | 2 |

| Manufacturer A | surge arrester 1 | 1,2 | 5,0 | ||||

| Manufacturer B | surge arrester 2 | 1,6 | 6,0 | ||||

| Manufacturer C | surge arrester 3 | 1,2 | 5,0 | ||||

| Manufacturer D | surge arrester 4 | 1,4 / 1,6 | 4,5 / 6,7 | ||||

| Protektel | PROXAR-IIIN AC | 2,4 | ≥ 1,6 | 11,0 | ≥ 7 | SM | 3 |

| Manufacturer A | surge arrester5 | 2 | 8,0 | ||||

| Manufacturer B | surge arrester 6 | 2,4 | 9,0 | ||||

| Manufacturer C | surge arrester 7 | 2,4 | 8,0 | ||||

| Manufacturer D | surge arrester 8 | 2,2 | 7,8 | ||||

The data presented above indicate that PROXAR arresters have much higher energy withstand. And this, in turn, translates into longer life and trouble-free operation of these devices. So if you're looking for surge arresters you can trust, keep in mind that in this respect PROXAR is ahead of the competition thanks to its energy strength parameters.

Possibilities of adjusting PROXAR parameters to your needs

As a manufacturer, Protektel has the ability to customise many of the parameters of the PROXAR surge arresters to the specific needs of the customer. For example, customization can concern:

- Ur/Uc parameter, which we can adjust to w network conditions or/and competitor's equivalent,

- the size of the insulating housing due to environmental conditions (creepage distance, dielectric strength),

- the size of the shield due to the customer's expectations to match the device or other equipment to the power system (changing the size of the mounting electrodes, the thread of the mounting holes and their arrangement),

- the operating point of the arrester due to the network conditions by adjusting the electrical and mechanical parameters and type of arrester,

- language version and description of nameplates.

We can also make the above mentioned modifications in the arrester equipment, i.e. line and ground terminals, mounting bases, additional fasteners, adapters, etc. This also applies to technical documentation, which in the case of individual projects also includes guaranteed data sheets with drawings (we provide drawing documentation not only in PDF, but also in DWG - CAD).

In addition, we offer:

- adjustment / reduction of production time of realization,

- delivery in batches,

- possibility to create warehouse stock,

- production according to schedule.

When you choose PROXAR, you get more than just a surge arrester

We all know that in million-dollar and critical investments, the choice of surge arresters is not just based on economics. In long-term operation, reliability and effectiveness of protection are equally important. And before that: professional and comprehensive advice. Protektel also adds full after-sales support.

It's no wonder that in more than twenty years of market presence, the company's surge arresters have already been chosen by more than 750 customers from the energy sector in Poland and abroad, especially from industry and RES. By July 2023, the factory in Przasnysz had already produced more 130,000 PROXAR units. This is probably the best proof of the unlimited trust that designers and investors have in this Polish brand of surge arresters.